Calender rollers / smoothing rollers for the converting and battery industry

Powerful and precise tools for your systems.

Powerful rollers for the converting and battery industry.

For decades, our durable, high-precision calender rollers and smoothing rollers have been used in a wide range of converting applications. Beyond that, we are known to the battery industry as an innovative and reliable partner for the manufacture and refurbishment of calender rollers for electrode production.

Benefit from a customized solution for your application – our product portfolio comprises a diverse range of concepts for electrically, water- and oil-heated as well as chilled rollers systems. The conscientious and careful design of grinding curves (crowning) is a matter of course for us.

We attach particular importance to perfect shape and position tolerances, even under the most demanding operating conditions. We guarantee the desired precision even at high operating temperatures and offer unique solutions with hardness values of up to 68 HRC and extreme hardening depths of up to 25 mm.

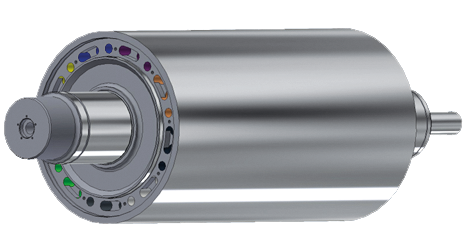

Example 3D-representation of a smoothing roller / calender roller

In most cases, smoothing rollers respectively calender rollers are provided with a coating in a final processing step – from hard chrome-plated roller surfaces to thermal spray coatings and special coatings. Based on our experience, we will be happy to advise you and to offer the optimum coating for your demand.

Contact person

Precision is not a coincidence, but the result of decades of experience.

Stefan Hesseling Senior Sales Manager Rollers ROLLERS stefan.hesseling@saueressig.com +49 2564 12 617